Ecotech Grand Prix 2021

Standing up for solutions to society's problemsManufacturing, IoT, artificial intelligence, materials, energy, etc. related to the environment.

We implement the technologies and thoughts of entrepreneurs and researchers in the ecotech field into society together.

News

- Ecotech Grand Prix

- Deep Tech Grand Prix

- News

- Ecotech Grand Prix

- News

- Agritech Grand Prix

- Ecotech Grand Prix

- Grand Prix

- Deep Tech Grand Prix

- News

- Biotech Grand Prix

- Food Tech Grand Prix

- Marintec Grand Prix

- Lifetech Grand Prix

- Agritech Grand Prix

- Ecotech Grand Prix

- Grand Prix

- Deep Tech Grand Prix

- News

- Biotech Grand Prix

- Food Tech Grand Prix

- Marintec Grand Prix

- Lifetech Grand Prix

Outline of the event

- point (e.g. of a statement)

- Scientific and technological "seeds" are being created in universities, research institutes, and corporate laboratories, but it takes a lot of effort before they sprout into practical applications. The Tech Planter, organized by LIVERNESS and its partners, is an ecosystem that aims to discover these seeds and serve as a planter to help them sprout into business. The Eco-Tech Grand Prix 2021 is a program aimed at discovering and fostering technological seeds and entrepreneurs in the real tech field (environment-related manufacturing, IoT, artificial intelligence, materials, energy, etc.).

Related Grand Prix :. List of Ecotech Grand Prix - subject (of taxation, etc.)

-

- Those who have a vision to change the world or improve the world based on the technological seeds in the real tech field and have a will to establish or develop a new business.

- Individuals and teams are both welcome to participate, even before incorporation.

- No limitation on the number of years of establishment, even if you are already a corporation. Even if you are close to mass production or PMF establishment, if you are planning to collaborate with partner companies, etc., it is acceptable.

- Application Theme

- Sustainability and Global Contribution

- Application period

- Monday, March 1, 2021 - Friday, July 9, 2021

- Screening Criteria

-

A panel of judges composed of LIVERNESS and its partners will review the following items

- 01novelty (patentability)

- 02feasibility

- 03Are you going to change the world?

- 04passion

- commendation

- Grand Prize: (300,000 yen cash prize + right to receive 5 million yen business investment) 1

Corporate Prize: (200,000 yen) Approximately 10 prizes will be awarded.

Schedule

- 3/1[MON]

-

Entry Start

this way (direction close to the speaker or towards the speaker)Please register as a member and fill out the web form to apply.

We also hold information sessions on a college-by-college and individual basis to encourage determination to enter and to teach tips on document preparation. Please feel free to contact us for more information.

- 6/26[SAT]

-

kickoff

RIVANES and its partners, as well as entered teams, will meet and mingle.

Business consultation and partnership development with each other will be available. Participation or lack of participation on the day of the event will not be considered.

- 7/12[MON]

-

1st round: Application Screening

A panel of judges composed of LIVERNESS and its partners will review the documents.

You will be asked to submit information about your team, skills, passions, and vision for the future via web form and video.

All applicants will be notified of the screening results and provided with feedback on their applications.

In addition, individual interviews (also online) for presentation review will be conducted for those who wish to participate.

- 8monthfirst 10 days of month

-

Finalists determined

Interviews will be held for applicants who pass the document screening to brush up their presentations for the final round.

In addition, meetings can be set up with partner companies for the purpose of business consultation and developing partnerships.

- 10/23[SAT]

-

Ecotech Grand Prix

The 12 finalist teams that pass the document screening will be screened for presentation.

- 10Month~

-

Matching Support Period

After the Demo Day, the contact point between the venture and LIBANES will continue to be open for discussions on commercialization.

We handle a wide range of start-up issues, from incorporation to prototype development, financing, R&D, and more.

In addition, collaborative matching between ventures and partner companies has become more active to support business development.

Partners

-

EBARA Corporation -

Kubota Corporation -

Sompo Japan Insurance Inc. -

Daikin Industries, Ltd. -

Nittetsu Engineering Co. -

Nihon Unisys, Ltd. -

East Japan Railway Company -

Mitsui Chemicals, Inc. -

Murata Manufacturing Co.

asset

- ASSET01Riverness Communicator

- ASSET02Partners

- ASSET03Professional Supporter

- ASSET04superfactory group

Support

- SUPPORT01Organize the purpose and vision of starting a business

- SUPPORT02Brush up on your presentation

- SUPPORT03Providing opportunities for business company collaboration

- SUPPORT04Support for R&D and prototype development

- SUPPORT05Support for knowledge and IP strategies

- SUPPORT06finance

Grand Prix Outline

- Grand Prix Name

- Ecotech Grand Prix 2021

- Location

- Center of Garage (1-16-3 Yokogawa, Sumida-ku, Tokyo)

- Date & Time

- Saturday, October 23, 2021, 13:00-19:00

- Application period

- Monday, March 1, 2021 - Friday, July 9, 2021

- Participation Target

- Held on a closed, pre-registration basis (finalists, partner companies, professional supporters, Super Factory Group)

- organizing

- Leave a Nest Co., Ltd.

- timeline

-

- 12:30-13:00

- inauguration

- 13:00-13:30

- Greetings from the Organizer

- 13:30~16:50

- Final Selection Presentations (Presenter①~⑫)

- 16:50-17:50

- Review Time

- 17:50-19:00

- Announcement of Judging Results and Award Ceremony

judge

-

-

head judge Executive Officer, CKO, LIVERNESS Co.Kazuhiro Hasegawa

- He holds a master's degree in engineering from Tokyo Metropolitan University. He joined RIVERNESS in his first year of master's degree and later became the first new employee of RIVERNESS. He launched the Human Resources Development Division and became an executive officer in 2012. In 2013, he moved to the Tokyo head office, where he is responsible for incubation projects in the manufacturing field, industry-academia collaboration projects, and the revitalization of manufacturing companies.

-

head judge

-

-

General Manager, Business Planning Department, Environmental Business Company, EBARA CorporationKeiji Sandalwood

- Joined EBARA CORPORATION in 1991. In the Environmental Plant Division, he participated in demonstration tests of a new exhaust gas treatment system for thermal power plants for six years from 1997 as an engineer in charge of technology. Then, for about 10 years, he participated in the construction project of a large-scale waste treatment facility overseas as a project manager. After working in the administration department, he joined the planning department in 2017, where he was involved in SDGs initiatives and new business development, etc. He will assume his current position in 2019.

-

-

-

Kubota Corporation Innovation CenterKen Matsumoto

Director, Water Environment Business Planning Office, Business Incubation Dept. - Joined Kubota Corporation in 1998 and engaged in overseas business related to water infrastructure. After working in the UAE and the U.S., he was appointed to his current position in April 2020. He is involved in open innovation activities with the theme of resource recycling solutions in the water and environmental fields.

-

-

-

Special Manager, Business Design Strategy Department, Sompo Japan Insurance Inc.Yusuke Shigesumi

- After joining the company in 1996, mainly engaged in the start-up and development of overseas business. He has been stationed in Russia, Indonesia, Germany, and Singapore. The last two years he was stationed in Israel, where he was engaged in scouting and business matching for startups with cutting-edge technology. He is working on launching a new business that will be the next pillar of revenue after the insurance business, nursing care business, and overseas business.

-

-

-

Deputy General Manager (Advanced Technology Research), Technology Innovation Center, Daikin Industries, Ltd.Yoshimasa Kikuchi

- Joined Daikin Industries in 1987. After joining Daikin Industries in 1987, he was engaged in the development of basic and elemental technologies for air conditioners in the Research Department, and at the same time, applied for an in-house entrepreneurship program and implemented project activities. He has served as Deputy Director of the Technology Innovation Center (in charge of compressors) and will be appointed Deputy Director of the Technology Innovation Center (in charge of advanced technology research) in September 2022.

-

-

-

General Manager, Engineering General Manager, Engineering Control Center, Nittetsu Engineering Co.Takeru Nishi

- Born in Fukuoka Prefecture in 1972 and raised in Oita Prefecture. Completed a master's degree in applied energy engineering at Kyoto University Graduate School of Engineering in 1997. In the same year, he joined Nippon Steel Corporation (now Nippon Steel Corporation). In the Engineering Business Division, he was in charge of new furnace start-up, process and equipment development for waste gasification and melting furnaces, and from 2012, worked on technological development and overseas commercialization of biomass fuel (pellets and bioethanol) production before assuming his current position in 2020.

-

-

-

General Manager, Public Works Division 1, Nihon Unisys, Ltd.Satoshi Kanai

- Joined Nihon Unisys in 1992. He was in charge of the public utility business department of electric power companies for many years, and worked on DX promotion in the energy field, such as deregulation of electric power.

Recently, he has been overseeing the creation of service businesses to achieve carbon neutrality. He aims to solve social issues related to the environment and people's lives.

-

-

-

Managing Executive Officer, Deputy General Manager, Business Creation Division, East Japan Railway CompanyTeruyuki Omote

- In 2000, he became the youngest president of Japan Restaurant Culinary Center, Inc. and later led the M&A of Nihonbashi Daiya and Kinokuniya as well as the development of Tokyo Station Gransta. He was appointed as Executive Officer and Deputy General Manager of Business Creation Division in 2016, and as Executive Officer in 2021.

-

-

-

Group Leader, Sustainability Group, R&D Planning and Administration Department, R&D Division, Mitsui Chemicals, Inc.Shinya Okazaki

- D. in Engineering from Kyushu University in 2000. Joined Mitsui Chemicals in 2001. In 2013, he joined the Petrochemical Business Division (now the Basic Materials Business Division), where he was in charge of large-scale overseas projects and engaged in the sales of technology licenses. He returned to the Production Technology Research Institute in 2017 and served as the director's staff and as the leader of the Chemical Process Group at the Osaka Plant before assuming his current position in April 2021. He is currently promoting R&D themes that contribute to carbon neutrality and the circular economy.

-

-

-

Executive Officer, General Manager, Business Incubation Center, Murata Manufacturing Co.Masamichi Ando

- D. in Engineering from the Department of Physics at Kwansei Gakuin University. 1988 joined Murata Manufacturing Co., Ltd. and developed and commercialized the world's first and smallest dielectric multi-mode antenna duplexer (for cell phone base stations). 2007 started research and development of piezoelectric polylactic acid (PLA) and commercialized organic piezoelectric film sensors in 2013. Discovered electrical antimicrobial activity of piezoelectric PLA in 2016. Established PIEECLEX, a joint venture with Teijin Frontier. Current position.

-

finalist

-

Murata Award

- Emulsion Flow Technologies, Inc.

- Representative】Hiroshi Suzuki

Connecting Limited Rare Metal Resources to the Future

Developed a new technology "Emulsion Flow Method" for highly efficient mixing and separation of water and oil droplets in solvent extraction. The new method enables low-cost, high-purity recovery of rare metals by using only one process of pumping liquid instead of the three processes of mixing, standing, and separating in the conventional extraction method. -

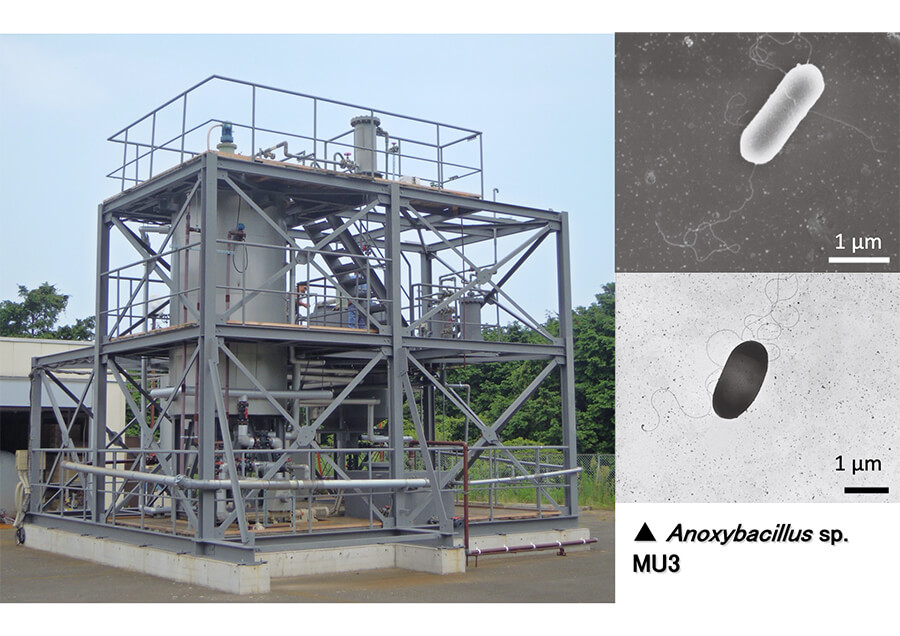

EBARA Award

- Chaperon Corporation

- Representative] Yasuhiro Ishibashi

Biogas power generation using a novel high-temperature solubilization technology

Pre-treatment using a new high-temperature solubilization technology improves the efficiency of methane fermentation. The company aims to implement a biogas power generation business using sewage sludge, food waste, and livestock manure as raw materials. -

Real Tech Fund Award

- Zip Infrastructure Corporation

- Representative] Takamasa Suchi

New urban transportation infrastructure, the bendable ropeway Zippar

The Zippar system allows for previously difficult curves between stations and can be built along roads, reducing the cost of private land acquisition and ocean reclamation, and contributing to the reduction of urban congestion. -

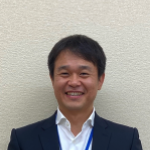

- Tsubame BHB Co.

- Representative] Koji Nakamura

Dispersed ammonia synthesis at low temperature and low pressure

Developed a small-scale on-site production ammonia synthesis system using electride catalyst technology to produce ammonia under mild conditions of low temperature and low pressure.

Breaking through the common sense of unipolar concentration and mass production, we will contribute to a society with less environmental impact. -

Kubota Prize

- I-Compology Corporation

- Representative] Hideki Koide

Biomass composite plastics reduce CO2 and marine debris

Develop new biomass composite plastic materials by combining carbon-neutral biomass with marine degradable plastics to reduce the use of plastics derived from fossil resources and solve the marine litter problem. -

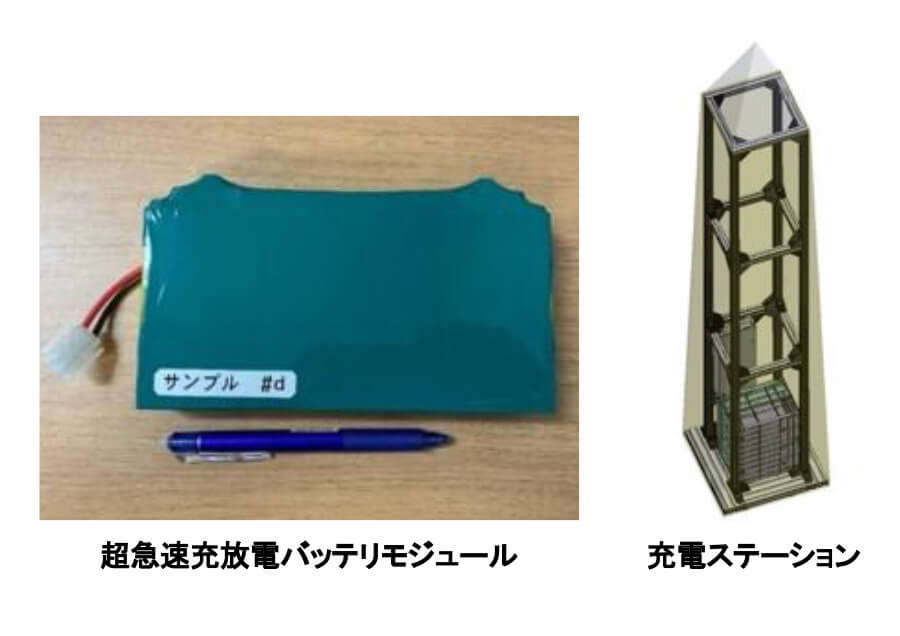

Sompo Japan Award / JR East Award

- Naturnix Corporation

- Representative] Yasuki Kanazawa

Development of next-generation rapid charging systems

Develop a charging station equipped with technology that simultaneously releases power from an electrical outlet and storage batteries, and a battery module compatible with ultra-rapid charging and discharging, to solve the charging time problem faced by electrified mobility and realize a society with ultra-rapid recharging. -

Nittetsu Engineering Award / Nihon Unisys BIPROGY Award

- Azos Corporation

- Representative] Kotaro Kawajiri

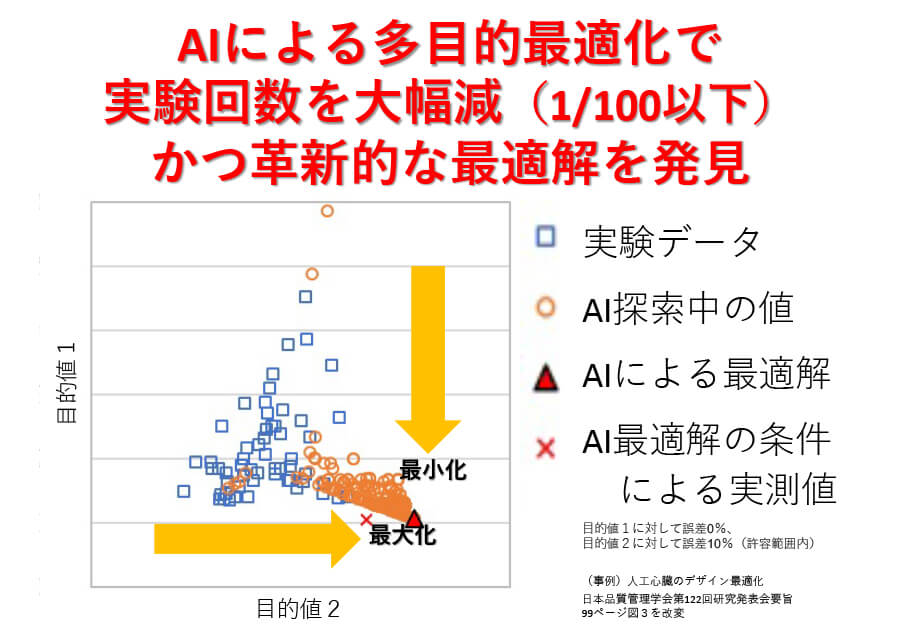

Innovation in R&D through multi-purpose optimized AI technology!

Multi-Sigma", an AI analysis platform, enables anyone to obtain multi-objective optimal solutions for manufacturing conditions, etc. from small amounts of experimental data in the cloud. The goal is to revolutionize research and development by popularizing an analysis platform that easily searches for solutions to conflicting objectives, such as cost and environmental impact. -

Grand Prize / Mitsui Chemicals Award

- Future Earth Institute, Inc.

- Representative] Yuji Matsukawa

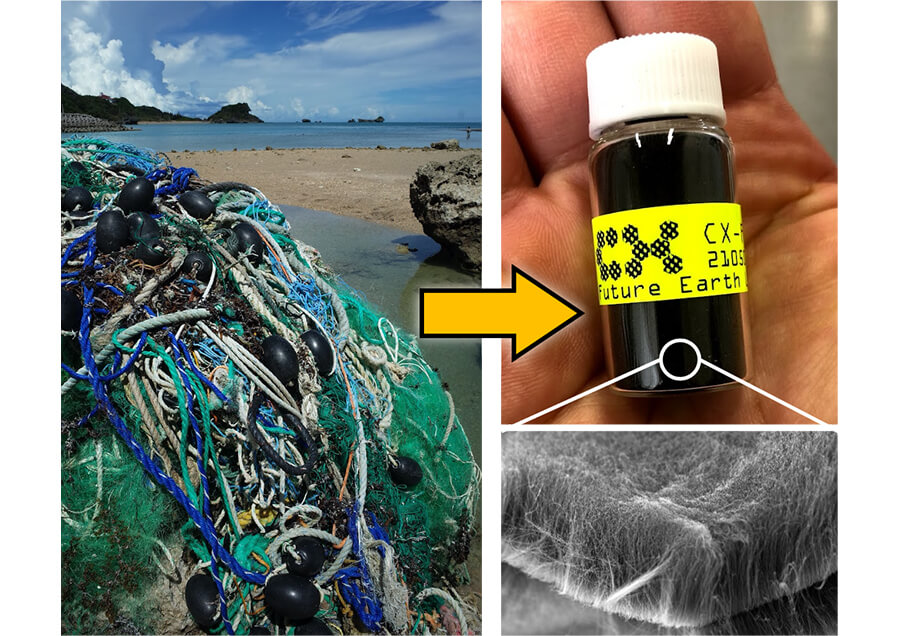

Development of a method for generating carbon nanotubes from plastic waste

Based on the concept of upcycling, which produces objects of higher dimension and value than the original product, we have succeeded in developing a device and method for highly efficient conversion of plastic waste, which has a high environmental impact, into carbon nanotubes, which have added value. -

- Basic Corporation

- Representative] Satoshi Sasaki

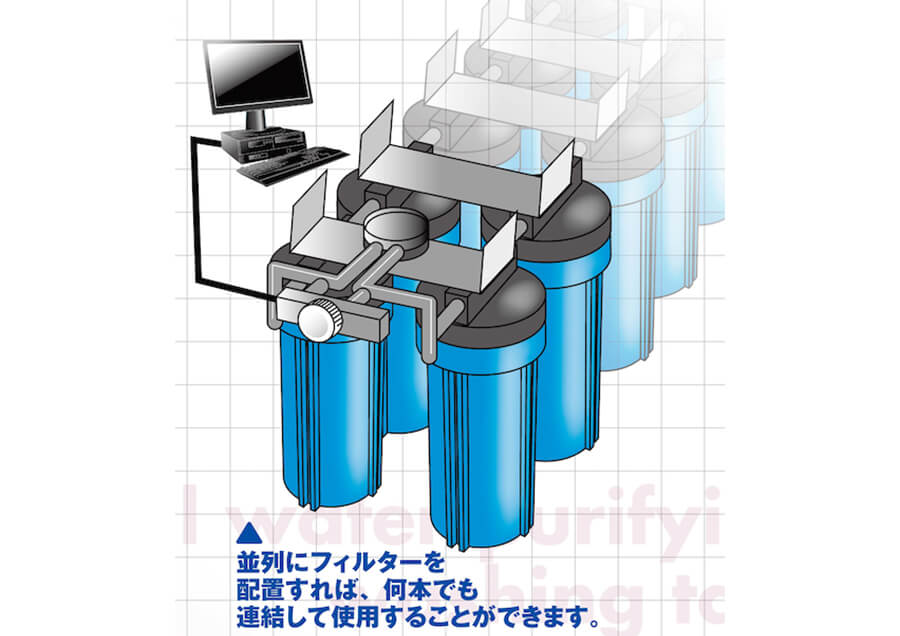

Water purification system to relieve the lack of drinking water for the poor

Attempts have been made to introduce water purification systems in developing countries, but these systems have failed due to high running costs and inability to be maintained locally. This system, with water purification back-flow cleaning at its core, will help alleviate drinking water shortages in areas where water supply infrastructure is underdeveloped. -

Daikin Award

- OKPOU

- Representative] Takashi Okubo

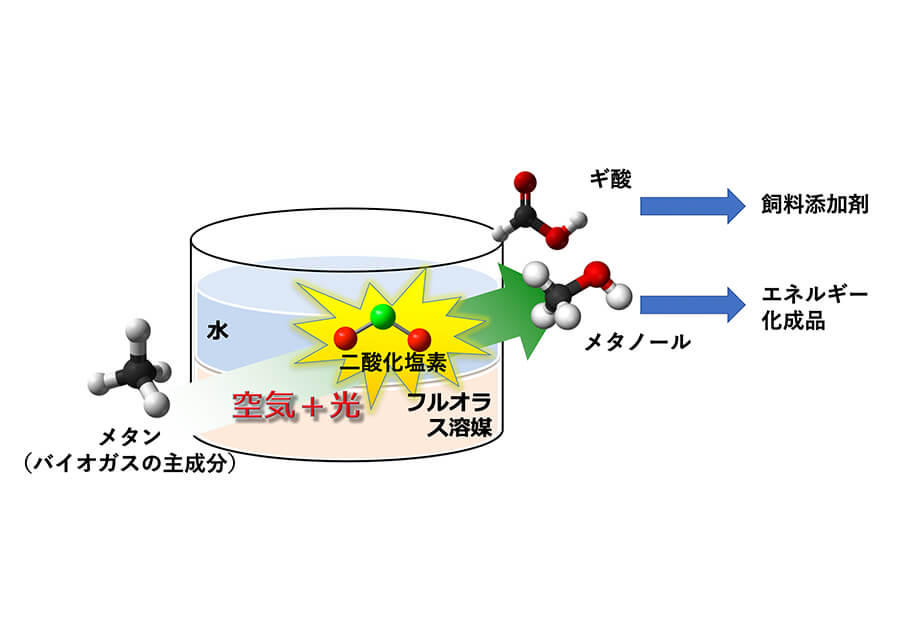

Biogas Chemical Conversion Technology for Carbon-Circulating Dairy Farming

Photo-reaction technology has been developed to convert methane gas obtained from biogas into methanol and formic acid. Using this technology, the company aims to synthesize carbon-neutral chemical products from livestock manure without using fossil fuels, and to build a recycling-oriented dairy farming business. -

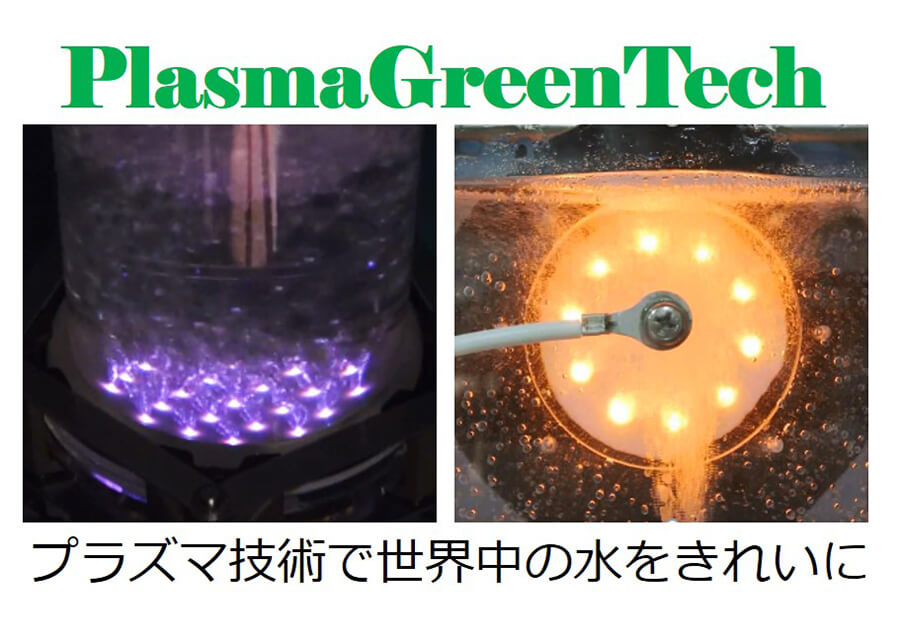

- PlasmaGreenTech

- Representative] Nozomi Takeuchi

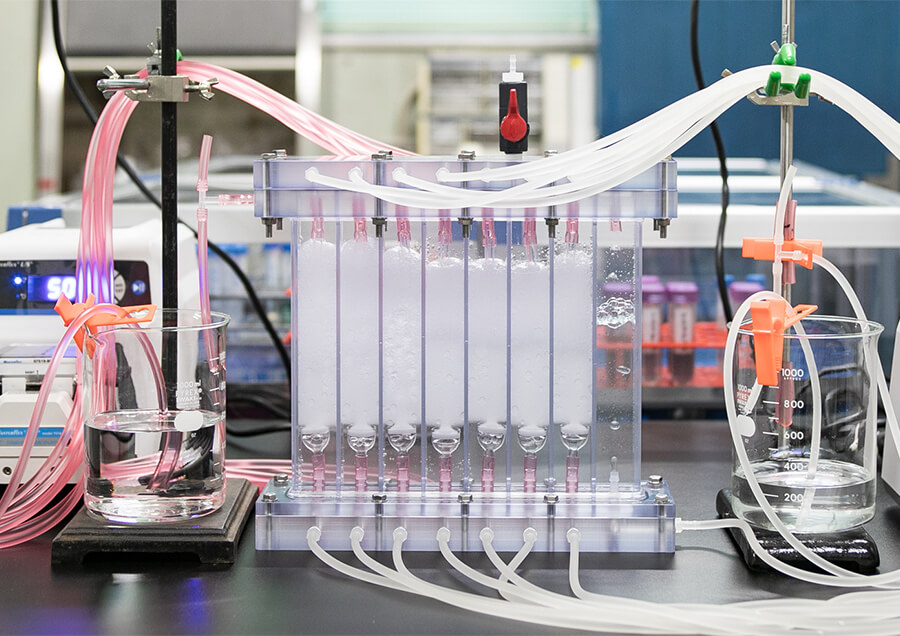

Gas-liquid interfacial plasma technology for clean water worldwide

Gas-liquid interface plasma is capable of decomposing persistent organic matter in water at room temperature and pressure. Since water purification is possible using only electrical energy, water treatment technology suitable for remote areas and developing countries will be developed to contribute to solving various water environmental problems around the world. -

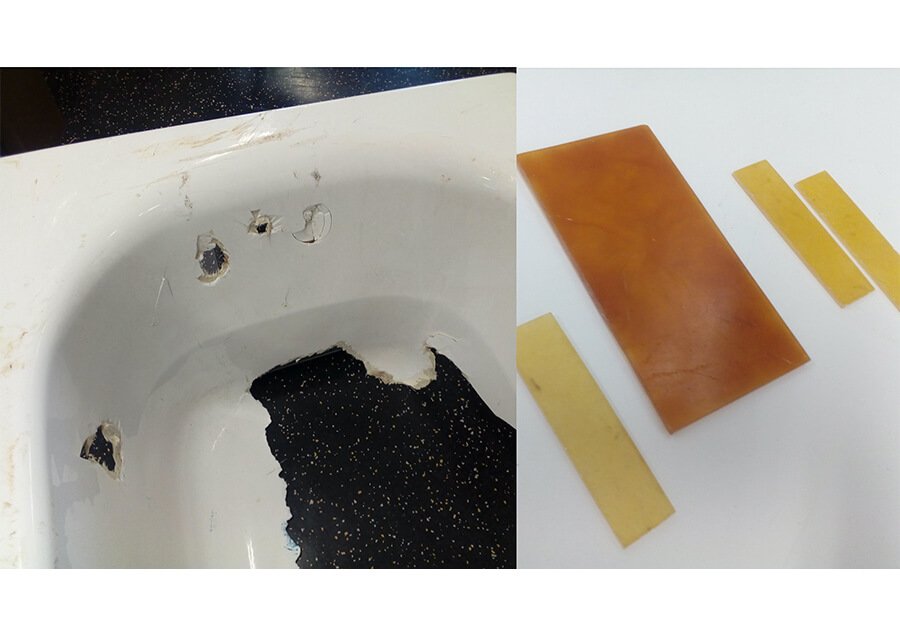

- bear's plastic (e.g. bear's hair)

- Representative] Kazutoshi Ikenaga

Complete recycling of high hardness composite material GFRP

Microwave-pressure decomposition technology enables recycling of glass fiber reinforced plastic (GFRP), a hard composite material used in bathtubs, small boats, etc., which is difficult to recycle and more than 95% is landfilled, into recycled GFRP.