Ecotech Grand Prix 2024

Confronting Solutions to Society's Challenges We will work together with entrepreneurs and researchers in the fields of environment-related manufacturing, IoT, artificial intelligence, materials, energy, etc., to implement their technologies and ideas in society. We implement the technologies and ideas of entrepreneurs and researchers in the eco-tech field into society together.News

- Ecotech Grand Prix

- Deep Tech Grand Prix

- News

- Ecotech Grand Prix

- News

- Agritech Grand Prix

- Ecotech Grand Prix

- Grand Prix

- Deep Tech Grand Prix

- News

- Biotech Grand Prix

- Food Tech Grand Prix

- Marintec Grand Prix

- Lifetech Grand Prix

- Agritech Grand Prix

- Ecotech Grand Prix

- Grand Prix

- Deep Tech Grand Prix

- News

- Biotech Grand Prix

- Food Tech Grand Prix

- Marintec Grand Prix

- Lifetech Grand Prix

Outline of the event

- point (e.g. of a statement)

- Scientific and technological "seeds" are being created in universities, research institutes, and corporate laboratories, but it takes a lot of effort before they sprout into practical applications. The Tech Planter, organized by LIVERNESS and its partners, is an eco-system designed to serve as a planter to discover these seeds and help them sprout into businesses. The Eco-Tech Grand Prix is a program aimed at discovering and fostering technological seeds and entrepreneurs in the real tech field (environment-related manufacturing, IoT, artificial intelligence, materials, energy, etc.).

Related Grand Prix :. List of Ecotech Grand Prix - subject (of taxation, etc.)

-

- Those who have a vision to change the world or improve the world based on the technological seeds in the real tech field and have a will to establish or develop a new business.

- Individuals and teams are both welcome to participate, even before incorporation.

- No limitation on the number of years of establishment, even if you are already a corporation. Even if you are close to mass production or PMF establishment, if you are planning to collaborate with partner companies, etc., it is acceptable.

- Application Theme

- Technology to create a sustainable society in harmony with the global environment

- Application period

- Screening Criteria

-

A panel of judges composed of LIVERNESS and its partners will review the following items

- 01novelty (patentability)

- 02feasibility

- 03Overseas Expansion Capabilities

- 04Are you going to change the world?

- 05passion

- commendation

- Grand Prize: (300,000 yen cash prize + right to receive 5 million yen business investment) 1

Corporate Prize: (200,000 yen) Approximately 10 prizes will be awarded.

Schedule

- 12/1[FRI].

-

Entry Start

this way (direction close to the speaker or towards the speaker)Please register as a member and fill out the web form to apply.

We also hold information sessions on a college-by-college and individual basis to encourage determination to enter and to teach tips on document preparation. Please feel free to contact us for more information.

- 6/22[SAT]

-

kickoff

RIVANES and its partners, as well as entered teams, will meet and mingle.

Business consultation and partnership development with each other will be available. Participation or lack of participation on the day of the event will not be considered.

- 7/7[SUN].

-

1st round: Application Screening

A panel of judges composed of LIVERNESS and its partners will review the documents.

You will be asked to submit information about your team, skills, passions, and vision for the future via web form and video.

All applicants will be notified of the screening results and provided with feedback on their applications.

In addition, individual interviews (also online) for presentation review will be conducted for those who wish to participate.

- 8monthfirst 10 days of month

-

Finalists determined

Interviews will be held for applicants who pass the document screening to brush up their presentations for the final round.

In addition, meetings can be set up with partner companies for the purpose of business consultation and developing partnerships.

- 9/14[SAT]

-

Ecotech Grand Prix

The 12 finalist teams that pass the document screening will be screened for presentation.

- 10Month~

-

Cooperation Discussion

After the Demo Day, the contact point between the venture and LIBANES will continue to be open for discussions on commercialization.

We handle a wide range of start-up issues, from incorporation to prototype development, financing, R&D, and more.

In addition, collaborative matching between ventures and partner companies has become more active to support business development.

Partners

-

Asahi Yukizai Co. -

Ando & Hazama Corporation -

Sanyo Chemical Industries Co. -

Daikin Industries, Ltd. -

Daiken Corporation -

Dai Nippon Printing Co. -

Tokai Carbon Corporation -

East Japan Railway Company -

Fujimori Kogyo Corporation (ZACROS)

asset

- ASSET01Riverness Communicator

- ASSET02Partners

- ASSET03Professional Supporter

- ASSET04superfactory group

Support

- SUPPORT01Organize the purpose and vision of starting a business

- SUPPORT02Brush up on your presentation

- SUPPORT03Providing opportunities for business company collaboration

- SUPPORT04Support for R&D and prototype development

- SUPPORT05Support for knowledge and IP strategies

- SUPPORT06finance

Grand Prix Outline

- Grand Prix Name

- Ecotech Grand Prix 2024

- Location

- center of a garage (1-16-3 Yokogawa, Sumida-ku, Tokyo)

- Date & Time

- Saturday, September 14, 2024, 13:00-19:00

- Application period

- Participation Target

- Held on a closed, pre-registration basis (finalists, partner companies, professional supporters, Super Factory Group)

- organizing

- Leave a Nest Co., Ltd.

- timeline

-

- 12:30-13:00

- inauguration

- 13:00-13:30

- Greetings from the Organizer

- 13:30-17:00

- Presentation (Presenter①~⑫)

- 17:00-17:50

- Review Time

- 17:50-19:00

- Announcement of Judging Results and Award Ceremony

- 19:00-19:30

- (cultural) exchange meeting

judge

-

-

head judge Director, Research Center for Human Resource Development, Riverness Inc.Haruna Kusunoki

- He holds a Master of Science degree from Yokohama City University's Graduate School of International and Comprehensive Studies. He was appointed as Director of the Human Resource Development Research Center in 2023 after serving as General Manager of the Teaching Materials, Education, and Human Resource Development Division. He has long been involved in next-generation education and the development of business-creating human resources for companies, and in 2021, he launched and oversees the business of LIVERNESS UNIVERSITY, which fosters leaders who can contribute to the Earth. Author of "Thinking Methods for Anyone to Become a Global Contribution Leader

-

head judge

-

-

Executive Officer, Deputy General Manager of Resin Division and General Manager of New Business Development Project, Asahi Yukizai Co.Hidehiro Kohrogi

- After joining Asahi Yukizai Corporation in 1995, he was engaged in the development of plastic materials such as phenolic resin molding materials for automotive applications and polypropylene pipes for use in chemical solutions. He also experienced joint research with universities for the purpose of exploring new businesses. While being involved in the product development work of the division as the head of the Resin Technology Development Department, he concurrently served as the head of the Advanced Materials Promotion Group, Advanced Materials Business Division from 2020, before assuming his current position in 2023. He aims to create new niche-top businesses by utilizing the Company's resources.

-

-

-

Executive Officer, General Manager, Technical Research Institute, Ando & Hazama Co.Hiroshi Taniguchi

- Joined Hazama Corporation (now Ando & Hazama Co., Ltd.) in 1988. After being assigned to the Technical Research Institute, he was mainly engaged in the development of concrete materials and construction technology. Experienced domestic and overseas civil engineering sites. He is currently expanding his perspective to technological development outside of his main business (construction field). After serving as General Manager of the Technical Planning Department, General Manager of the Civil Engineering Research Department, and General Manager of the Advanced Technology Development Department, he assumed his current position.

-

-

-

General Manager, Business Planning Department, Sanyo Chemical Co.Kotaro Kitano

- After joining Sanyo Chemical in 2002, he was mainly involved in the development of polymerization toner intermediates in the Research Division, and moved to the Sales Division in 2006, where he was involved in sales of polyols (raw materials for polyurethane) and thermoplastic polyurethane resin powder. In 2016, he was transferred to our subsidiary in the U.S., where he was involved not only in maintaining and expanding existing business, but also in developing new business and building partnerships with other companies, etc. He has been in his current position since August 2023. He will be involved in new business development, etc.

-

-

-

Chief Engineer, Technology Innovation Center, Daikin Industries, Ltd.Isamu Shigemoto

- In 1997, he joined Toray Industries, Inc. While engaged in computational polymer science using quantum chemical calculations, molecular simulations, and materials informatics, he also served as an advisor for Moonshot Goal 6, an advisor for JST ACT-X trans-scale area, and a member of the Supercomputer Industrial Application Council and the Computational Materials Science Council, etc., and was instrumental in industry-government-academia collaboration. In 2023, he joined Daikin Industries, Ltd. and became the Chief Engineer of Technology Innovation Center.

-

-

-

General Manager, Development Planning Office, R&D Center, Daiken CorporationShigeki Ishiguro

- Joined Daiken Industries, Ltd. in 2004. Assigned to the research department, he was involved in the development of wood interior building materials and the research and development of interior building materials that contribute to energy conservation and comfort. From 2022, he has been in charge of development planning at his current position, promoting R&D and co-creation activities with universities to realize a circular economy.

-

-

-

General Manager, Development Division, Living Space Business Department, Dai Nippon Printing Co.Tadashi Nakajima

- Joined Dai Nippon Printing Co. Assigned to the Business Forms Division, he was engaged in product and technology development of form and card products. After performing evaluation and analysis work as a head office researcher, he was in charge of material development strategy planning to development, as well as overall research and development, and is currently the general manager of the Development Division of the Living Space Business Department.

-

-

-

Manager, New Business Promotion Department, Tokai Carbon Co.Hiroto Nakamura

- After working for a materials manufacturer and a precision machinery manufacturer, he joined Tokai Carbon Corporation in 2019. He has been in his current position since March 2024. Currently, he is working hard to create new businesses in the carbon field that do not depend on fossil fuels and in the non-carbon field, based on the concept of "decarbonization.

-

-

-

Deputy General Manager (Chief), Shinagawa Unit, City Planning Division, Marketing Headquarters, East Japan Railway CompanyMotomura, Hibiki

- After joining East Japan Railway Company in 2006 and gaining experience in station building store operations, tenant leasing, and land and elevated property management, he has been in charge of the Shinagawa development project since 2016. From April 2022, he was stationed in Silicon Valley for about a year and a half, and after returning to Japan, he led the construction of a startup ecosystem in TAKANAWA GATEWAY CITY. He was also involved in the launch of the overseas CVC "JRE Ventures".

-

-

-

(ZACROS) Executive Officer, General Manager of Functional Container Business Department, Environmental Solution Business Division and General Manager of Business Planning DepartmentShinichiro Kimura

- Joined Fujimori Kogyo in 1999. Since joining Fujimori Kogyo in 1999, he has been involved in problem-solving sales activities using flexible packaging materials for the food market for 10 years. After a career in marketing and the Human Resource Center, he assumed responsibility for the packaging and container business in April 2024. He aims to provide new value to society as a whole by working on the transformation of business models that contribute to solving social issues, such as the realization of a circular economy.

-

finalist

-

- amu corporation

- Representative] Shohei Ashihara

Turning the common sense of value from fishing gear upside down with a knitting tool.

The company will manufacture recycled materials from discarded fishing gear, which is also a direct cause of the ocean plastic problem. By selling recycled materials to companies seeking them as a material brand, the company will create a mechanism to solve social problems through business. -

Ando Hazama Award

- GYXUS Corporation

- Representative] Tomitaro Hirata

Creating a World Without Burying Gypsum Board Waste on Earth

Gypsum board waste will be generated in large quantities worldwide in the future. However, recycling methods for this waste have not been established, and this is causing landfill sites to become strained. With horizontal recycling technology to recycle gypsum board at its core, we will create a world where waste is not buried on the earth. -

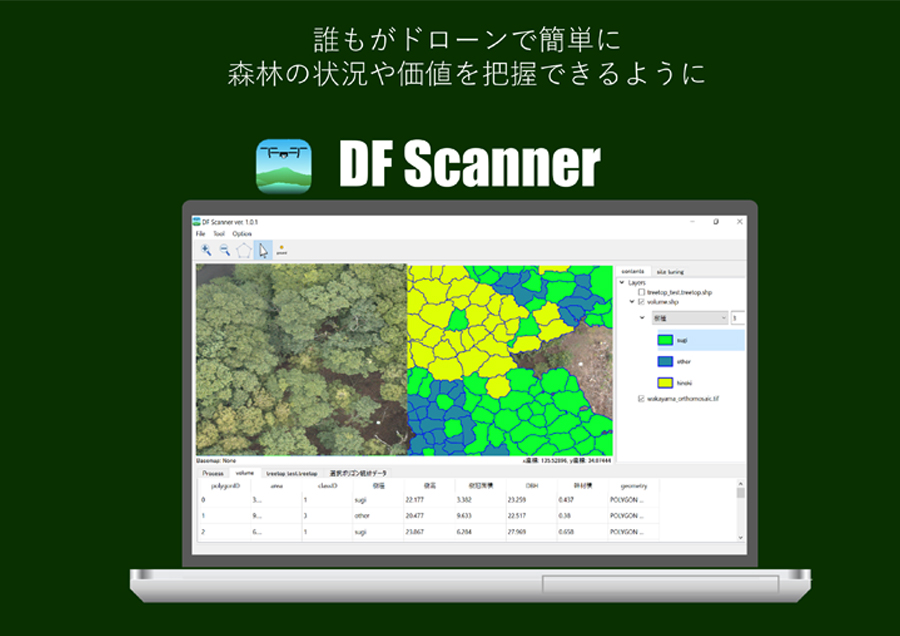

- DeepForest Technologies, Inc.

- Representative] Kengo Ikehata

Drones and AI give new shape to forest management and conservation

Forests are being evaluated for new values as a CO2 sink and a place for biodiversity conservation, and a system to evaluate these values quantitatively and over a wide area is needed. We will utilize drones and AI to create a system that enables efficient observation and management. -

Daikin Award

- Tensor Energy Corporation

- Representative] Nana Hori

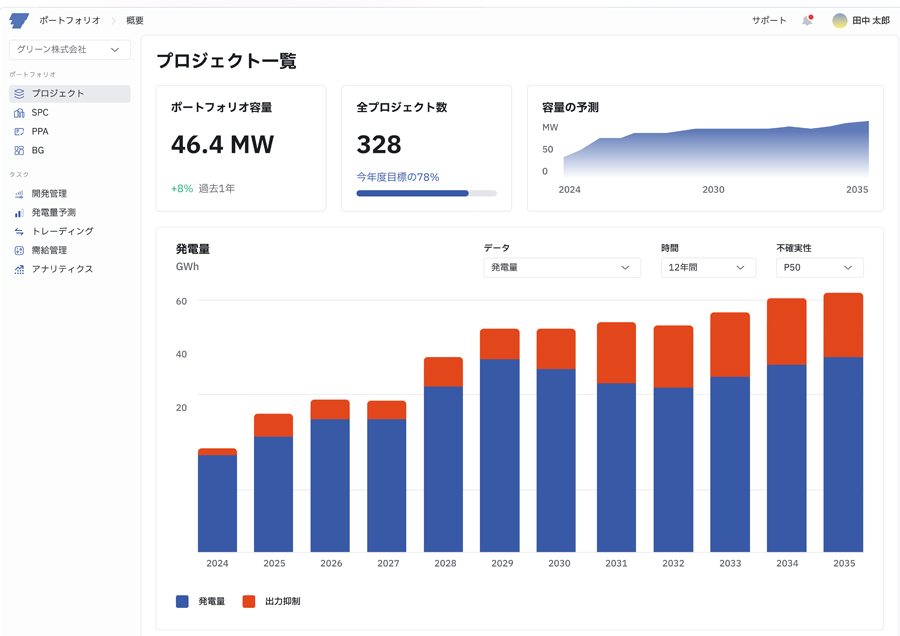

Efficient use of renewable energy and stabilization of electricity supply

Renewable energy is difficult to manage due to the dispersion of power plants, but cloud architecture, power generation, market price and demand forecasting algorithms, and IoT technology will enable each power plant to forecast, manage, and optimize its energy supply using storage batteries to achieve sustainable energy supply. -

Tokai Carbon Award / ZACROS Award

- Innovare Corporation

- Representative] Mitsutaka Kawatani

Creation of new bio-based raw materials through practical application of natural rubber seed

Focusing on natural rubber seed, which had been neglected as an unutilized resource. The company aims to create a new market for raw materials derived from natural rubber seed by developing raw materials for various bio-products and biochar, which are in short supply around the world. -

- colourloop Inc.

- Representative】 Motoko Uchimaru

Colour Recycle System that circulates materials by color

Through the "Colour Recycle System," a new sorting method that focuses on the color of waste textiles, which is difficult to sort by material, we create new values and create and offer attractive materials and products that are highly desirable to general consumers. -

Asahi Yukizai Award

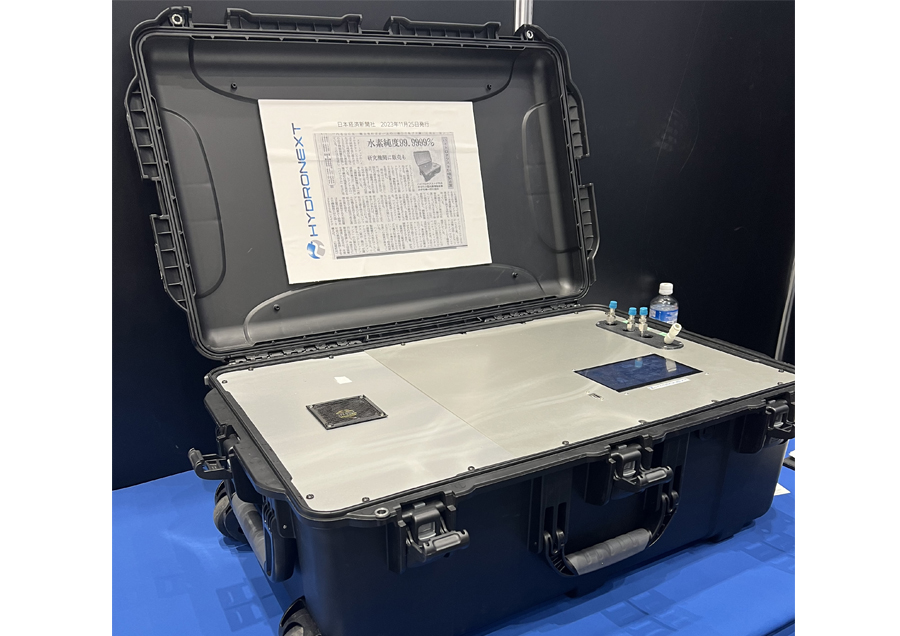

- Hydronext Corporation

- Representative] Masaaki Nagai

Development of ultra-pure hydrogen purification technology using metal membrane separation method

Purify 99.9999% high purity hydrogen from unused gas and biomass to achieve a sustainable society. Using metal membrane permeation technology, we will construct a hydrogen recycling and utilization system utilizing waste plastic gas and industrial by-product gas. -

JR East Award

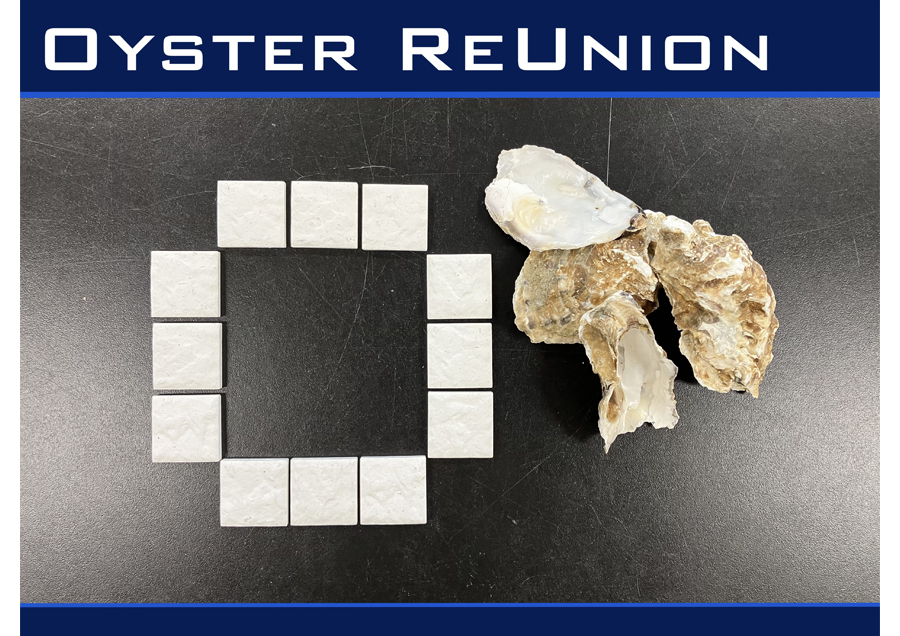

- Oyster ReUnion

- Representative] Yoshitaka Matsumoto

Development of high-performance oyster shell tiles that absorb carbon dioxide

In response to the problem of discarded oyster shells, which have accumulated in large quantities in recent years and have nowhere to go, and the depletion of tile raw materials, we are developing smart oyster shell tiles as a representative eco-friendly and highly functional (humidity control and odor absorption) building material, taking advantage of the material's ability to absorb carbon dioxide during the manufacturing process. -

Grand Prize / Sanyo Chemical Award

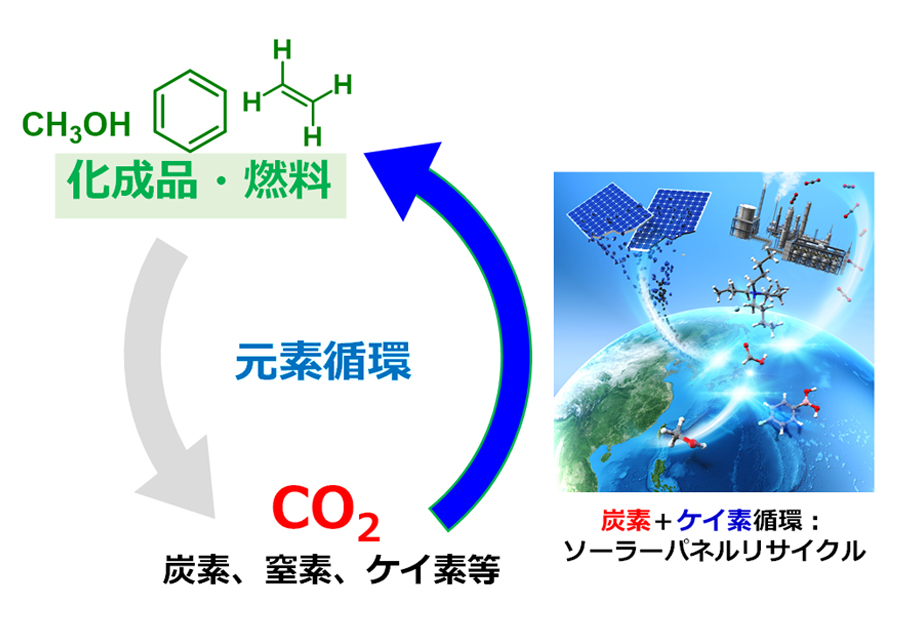

- element-neutral

- Representative] Ken Honkura

CO2 conversion reaction using silicon reductant

There are various issues stemming from the circulation of resources (elements), such as CO2 emissions and waste solar panels. 2 recycling is realized by a reaction system that creates useful organic materials by utilizing waste silicon from used panels as a CO2 reductant. -

DNP Award

- Unabes

- Representative] Yui Okuda

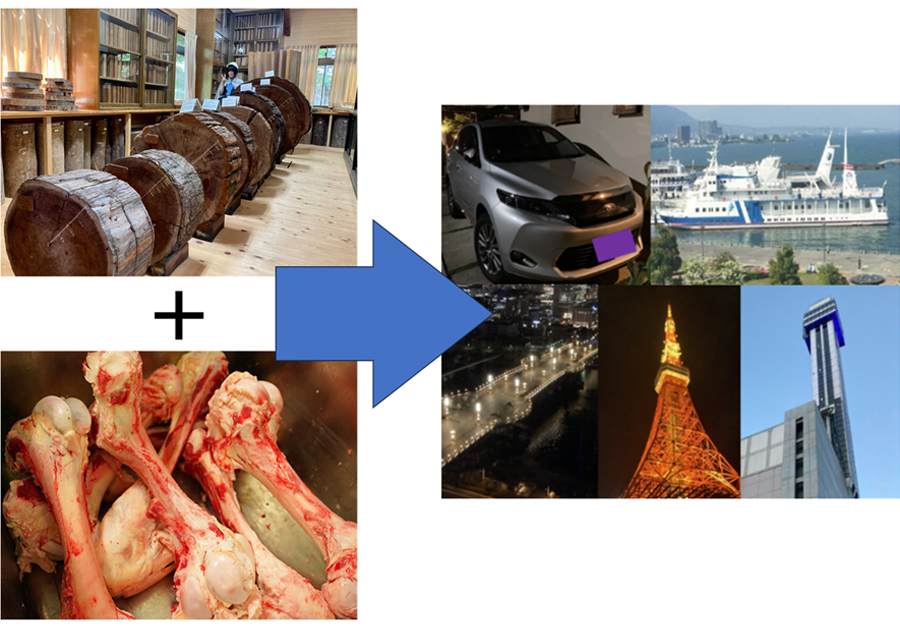

Development of Highly Tough Biomass Materials Composed of Plants and Inorganic Materials

By mimicking bones and shells, and by compositing fibers such as wood, plants, or cellulose obtained from them with inorganic components of livestock bones and shells, and then treating them with fatty acids, we will develop tough and highly water-resistant biomass structural materials with excellent toughness. -

DAIKEN Award / Real Tech Fund Award

- Resource Recycling Innovation

- Representative] Kazuhide Ishii

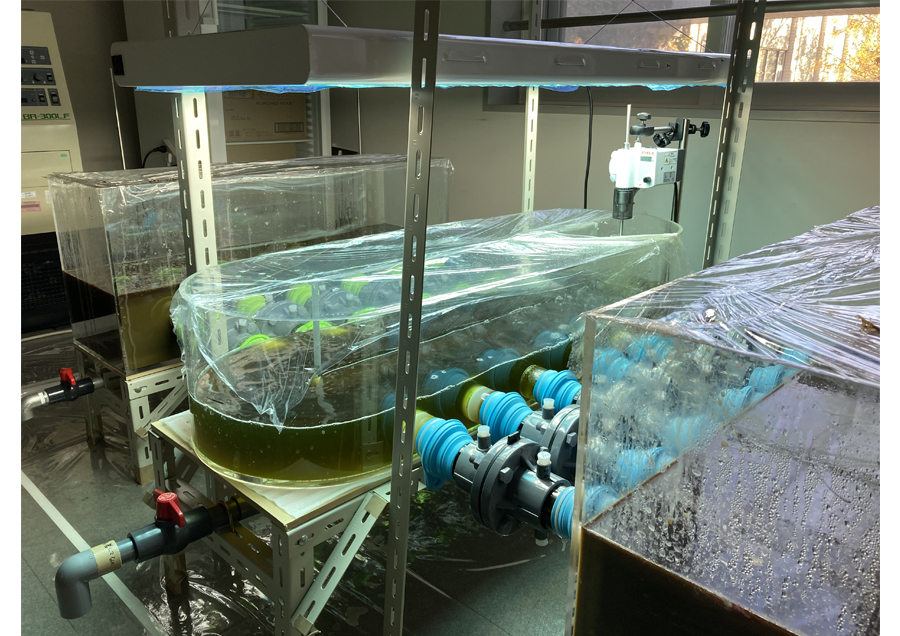

Innovative Nitrogen Cycling System: Algae Production with Bio-liquid Fertilizer

Develop innovative diffusion-driven microalgae reactors and establish high-value-added microalgae cultivation technology using excess bovine manure methane fermentation digestate (bio-liquid fertilizer) to achieve sustainable food production that reduces environmental pollution and improves nitrogen cycle efficiency. -

- Water Processing Systems

- Representative] Naohiro Nishikawa

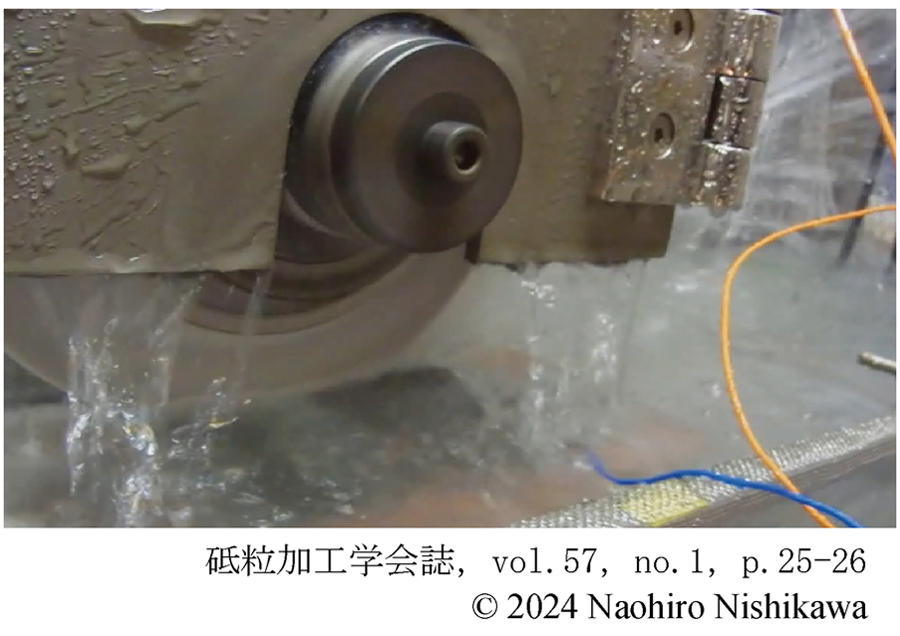

Improvement of manufacturing sites through environment- and people-friendly water processing systems

One of the factors contributing to 5K in manufacturing sites is processing fluids containing chemicals such as oils used in machining. We aim to commercialize and socially implement a water processing system that is cleaner, reduces waste fluid, and reduces CO2 emissions by using water as the processing fluid without the use of chemicals and through electrochemical corrosion prevention, etc.